FIRST-CLASS PRODUCTION PROCESS EFFICIENCY

3CONnect IXCHANGE Manufacturing Execution Sys

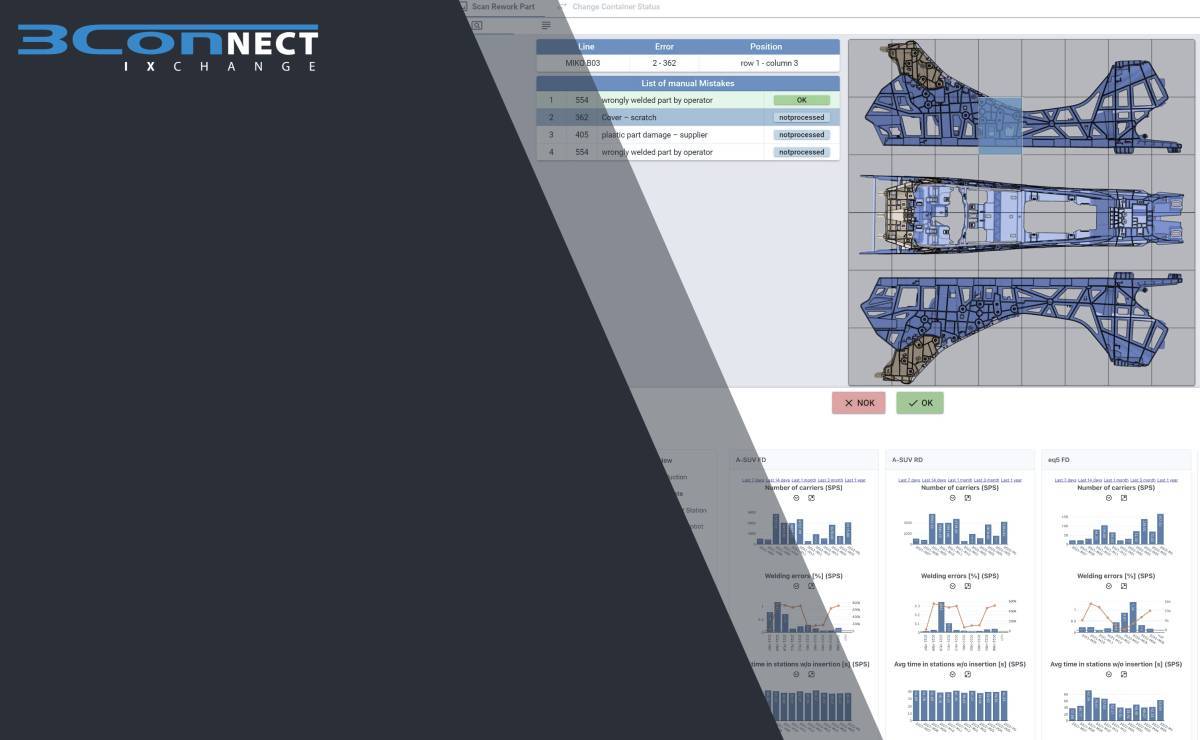

MES 3CONnect I X C H A N G E coordinates, controls and monitors the production process in real time. We built our software concept on over 20 years of machine and systems engineering experience.

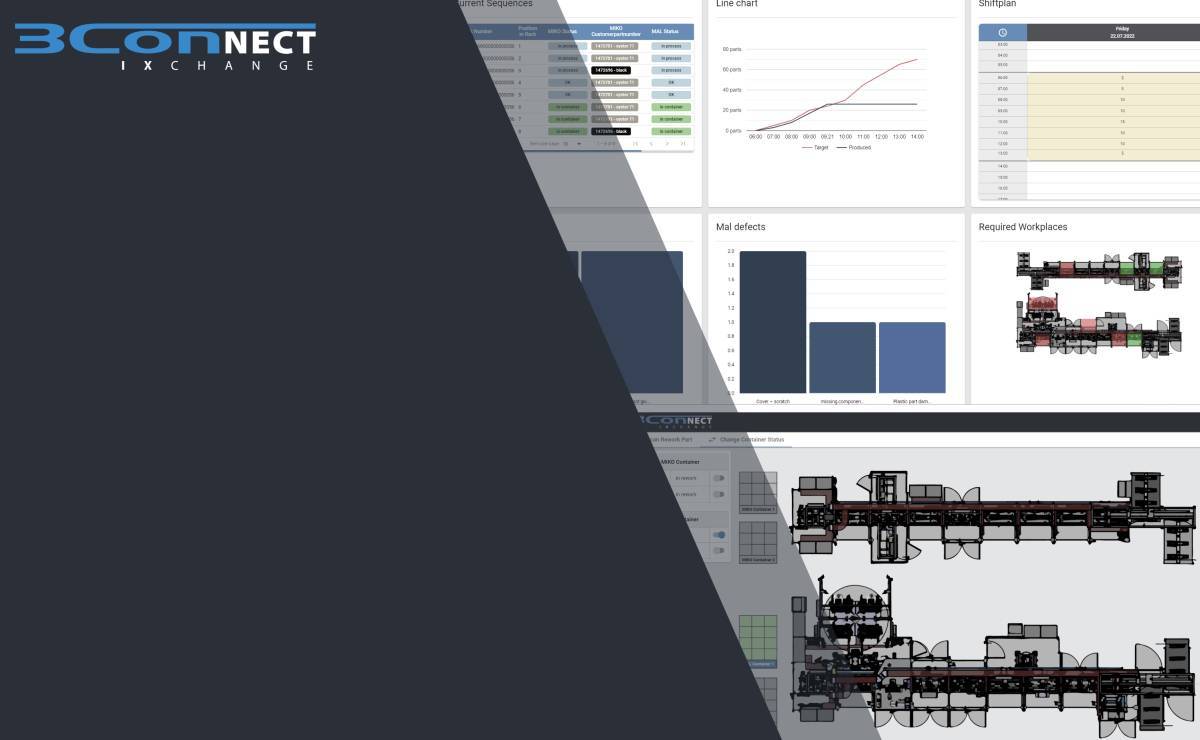

01 ACCURATE ORDER PROCESSING

- Sequential processing (JIS) of orders: Precise order management even

with a high number of variants and complex process dependencies - Data Import | Control | Tracking:

– Import of production information from external source

– Corresponding control of the production process by the MES

– Continuous transmission of production information from each individual station of the production line (such as welding times) to the MES and storage on an external system for later analysis - Track and Trace: End-to-end part and component tracking and tracing from the warehouse to pretreatment and from treatment/processing to preparation for dispatch

- Validation and shipping: Specification and quality check (cross check via the blind audit screen display) and assignment to the target container of each individual part via QR code

02 OUTSTANDING PRODUCTION AND ASSEMBLY MANAGEMENT

- Continuous performance validation with reference to the performance indicators

- Efficient order processing by improving the technical processes which can be measured based on waiting times, processing time, machine utilisation, and machine availability

- EOL - End-of-line quality inspection with OK part/rework part classification

- Marking of the defects directly during production on the rework screen

- Return of the manually corrected parts into JIS production possible

- Production monitoring: Real-time display of scheduled vs. completed productions

- Continuous cycle time analysis of all integrated lines, stations and processes

- Big data analysis: Real-time performance analysis of all integrated lines, stations and processes

03 COMPREHENSIVE SYSTEM

- Single source from MES to PLC

- Connectivity to all standard ERP systems

Keyfacts

Fields of application

Media

Contact

Our experts are happy to advise you.